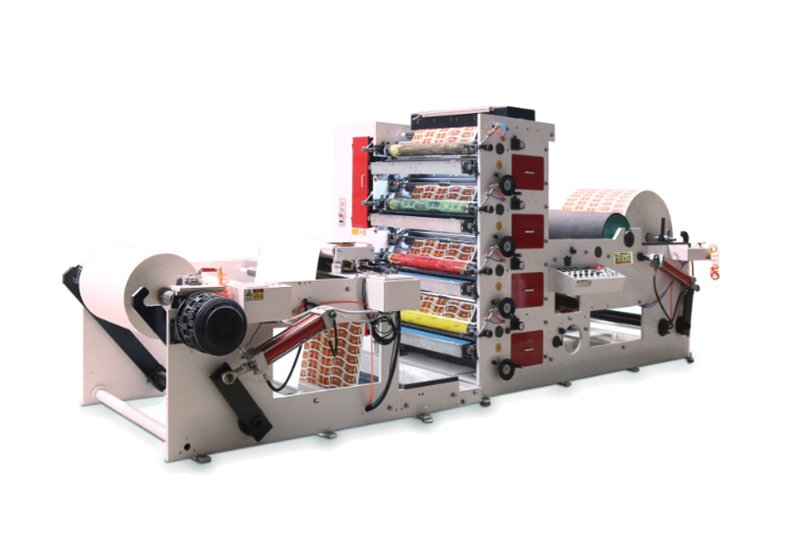

1.Versatility

Flexo Printing Machine can print on a wide range of substrates, including non-porous materials like plastic, metallic films, and foil, as well as porous materials like paper and cardboard. This versatility makes them ideal for flexible packaging, labels, corrugated boxes, and more.

2.High-speed printing

Flexographic presses are capable of high-speed production, making them efficient for large volume runs. This is particularly advantageous in industries where fast turnaround times are critical.

3.Cost-effective

They are generally more cost-effective than other printing methods, especially for long print runs. The setup costs are lower, and once running, they can produce prints quickly and economically.

4.Ability to use water-based and UV inks

Flexographic presses can use a variety of inks, including water-based and UV-curable inks. This flexibility allows for printing on different substrates and achieving various visual effects.

5.Consistent quality

Modern Flexo Printing Machine are equipped with advanced controls for tension, registration, and color management, ensuring consistent print quality throughout the print run.

6.Adaptability to automation

Flexo Printing Machine can integrate with automated systems for tasks such as plate mounting, ink mixing, and job setup, enhancing productivity and reducing manual labor.

Overall, the advantages of Flexo Printing Machine make them a preferred choice for many packaging and label printing applications, where speed, versatility, and cost-effectiveness are crucial factors.

GET A QUOTE