Flexographic printing, commonly referred to as flexographic printing, is a modern printing technology widely used in the packaging industry. Known for its versatility, speed and ability to print on a variety of substrates, flexographic printing has become the cornerstone of high-volume printing. At the heart of the process is the flexographic printing press, a precision device that enables efficient, high-quality printing. This article explores the basics of flexographic printing, the role of the flexographic printing press, its applications, its advantages, and how it compares to other printing methods.

Flexographic printing is a form of rotary printing that uses flexible relief plates and quick-drying inks. It is primarily used for printing on non-porous materials such as plastics, metal films, glass paper, and paper. The process involves transferring ink from a raised image on a flexible plate to a substrate, usually using a rotating roller.

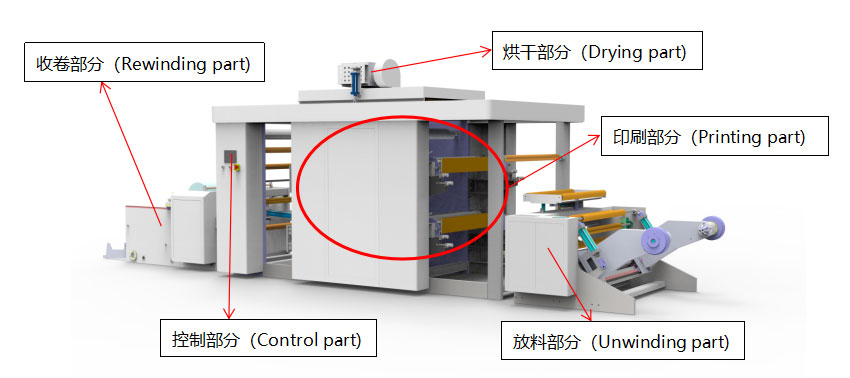

At the heart of the process is the flexographic printing press, which consists of several key components:

1. Anilox roller: A roller with tiny cells that meter the amount of ink transferred to the plate.

2. Plate Cylinder: Holds the flexible plate, which carries the image to be printed

3. Impression Cylinder: Applies pressure to ensure substrate is in contact with the plate.

4. Inking System: Delivers ink to the anilox roller.

5. Drying System: Ensures ink dries quickly to prevent smudging.

DAKIOU Flexo Printing Machine are designed to handle high-speed production while maintaining consistent print quality, making them an essential tool in modern printing operations.

Flexographic printing is versatile and is used across a wide range of industries. Some common applications include:

Packaging: Flexible packaging, corrugated boxes, labels, and bags.

Food and Beverage: Printing on wrappers, pouches, and containers.

Pharmaceutical: Labels and packaging for medical products.

Consumer Goods: Printing materials for household products, cosmetics, and more.

Newspapers and Magazines: High-speed printing for large circulations.

Flexographic printing presses: are particularly well suited to these applications because they are able to print on uneven surfaces, making them ideal for packaging materials that require durability and high-quality graphics.

1. Versatility: Flexographic printing can print on a variety of materials, including plastics, paper, foil, and more.

2. Speed: Flexographic printing presses are one of the fastest printing methods and are suitable for high-volume production.

3. Cost-effectiveness: Flexographic printing is efficient and produces less waste, making it an economical choice for high-volume printing.

4. Environmentally friendly: Water-based and UV-curable inks used in flexographic printing are more environmentally friendly than solvent-based inks.

5. High-quality output: Technological advances ha ve improved the resolution and color accuracy of flexographic printing, making it more competitive with other methods such as offset and digital printing.

Flexographic vs. offset printing: Offset printing is better suited for high-detail, flat surfaces (such as paper), while flexographic printing is better suited for uneven or non-porous materials. Flexographic printing pressesare also faster and more cost-effective for high-volume printing.

Flexo vs. Digital: Digital printing offers greater flexibility for short runs and variable data printing, but flexo presses are more efficient for high-volume production and specialized substrates.

Flexo vs. Gravure: Gravure offers superior image quality, but is more costly and less flexible in terms of substrate compatibility.

Flexography is a dynamic and adaptable printing method that plays a critical role in the packaging and printing industries. The flexo printing machine is at the core of this process, enabling high-quality prints on a variety of materials with unmatched speed and efficiency. As technology continues to evolve, flexo printing and the flexo printing machine are poised to remain key players in the world of modern printing.

Whether you're in the business of packaging, labeling, or large-scale printing, understanding the benefits and applications of flexography and the flexo printing machine can help you make informed decisions for your printing needs.